Mineral processing – Milling

Practical Action

In general, the harder the material, the more specialised and expensive the type of mill used

has to be. In addition if a particular mill can be used over a range of hardness scales, the

harder the material the lower the throughput for a given size requirement. Another

characteristic of a material to be aware of is brittleness, which is the degree to which a

material will easily break. Most minerals are brittle, as opposed to metals which are ductile,

although some to a greater degree than others. Brittleness does not equate with hardness as

brittle materials can be hard or not particularly hard. Materials which are not brittle to some

degree, metals or soft plastics for example, cannot easily be milled.

Free moisture content of a material should be as low as possible for dry milling. In practice

this can be a problem, especially in humid regions where the moisture can cause the material

to stick to the grinding media. Different mills behave in different ways with moist materials

and in some cases drying of the raw materials is required.

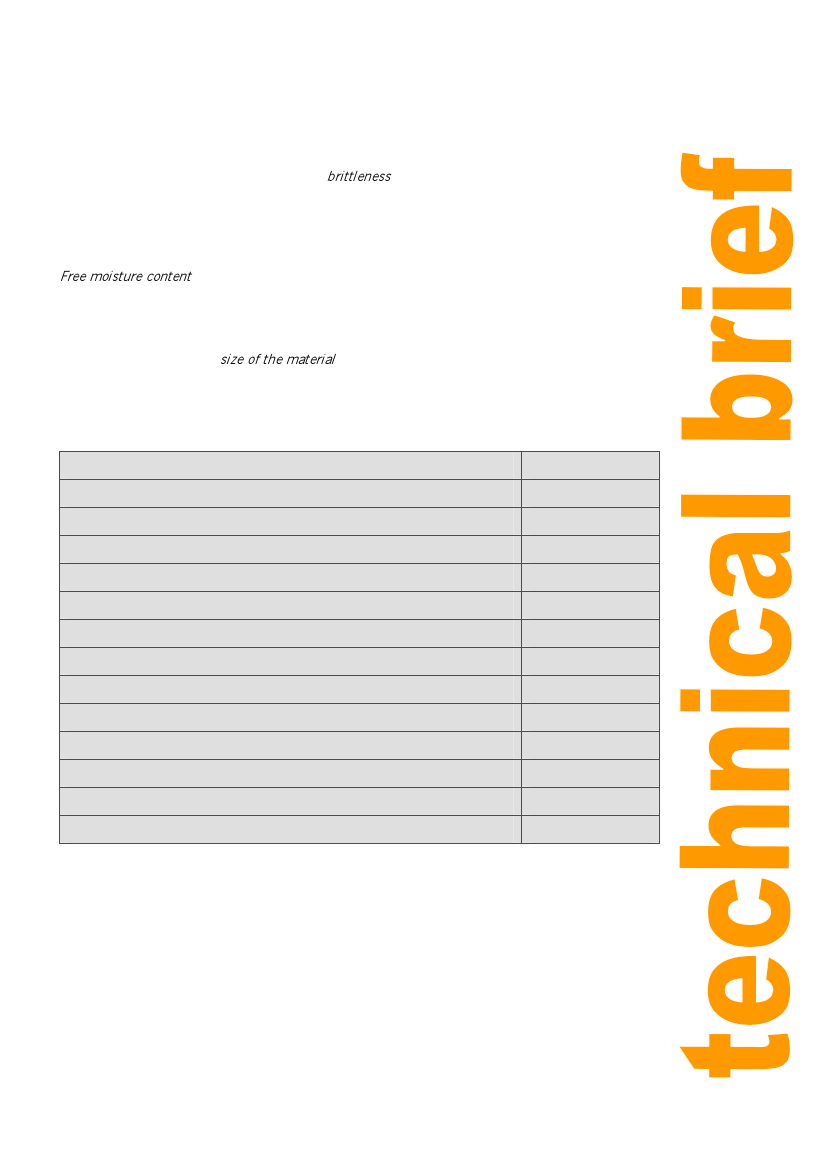

Also important is the final size of the material in question. Table 3 below gives details of some

materials which are milled and the degree of fineness required. Specifiers may stipulate that

a proportion of the material is finer than a particular size. Usually this proportion is 90% or

95% but may be 99% for particularly demanding applications. In certain applications a

particular range of particle sizes may be required.

Material and Application

Feldspar - (flux in ceramics)

Talc - (paper making and cosmetics)

Limestone - (agricultural lime)

Ordinary Portland Cement

Chalk

Powdered charcoal or coal for fuel briquettes

Pigments for Paints (various materials)

Silica quartz (glass making)

Phosphate (fertiliser)

Iron Ore

Lime (industrial applications such as detergents)

China clay

Alumina

Table 3: Material Particle Size

Particle Size in mm

0.075

0.01

1.2

< 0.10

0.05

<0.10

~ 0.005

0.01

0.075

0.20

0.10

0.002

0.005

Characteristics of Mills

Types of mills

In this brief we categorise mills in 3 groups:

1. Low-speed tumbling mills

2. Roller mills

3. Very fine grinding mills, which include the following types of mill:

• High speed pulveriser or hammer mill

• The vibrating mill

• Pin mill

3